Company

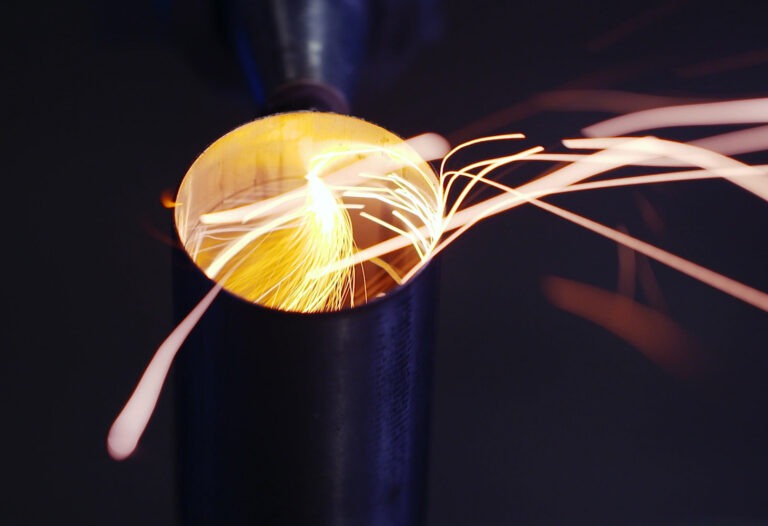

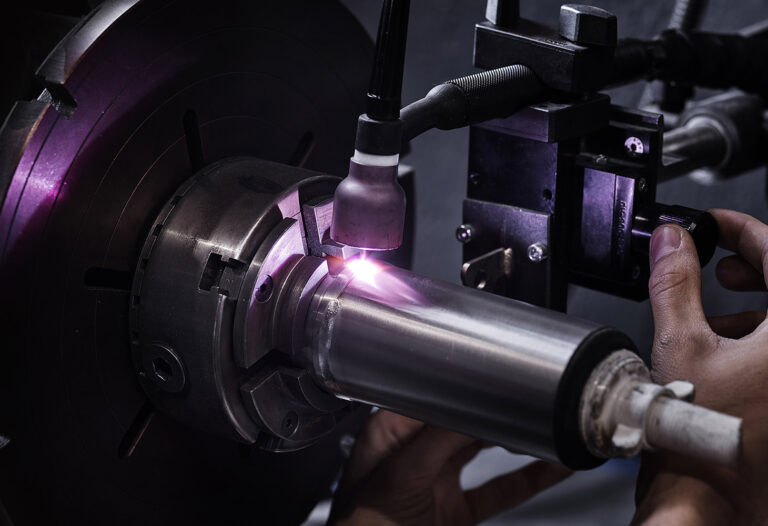

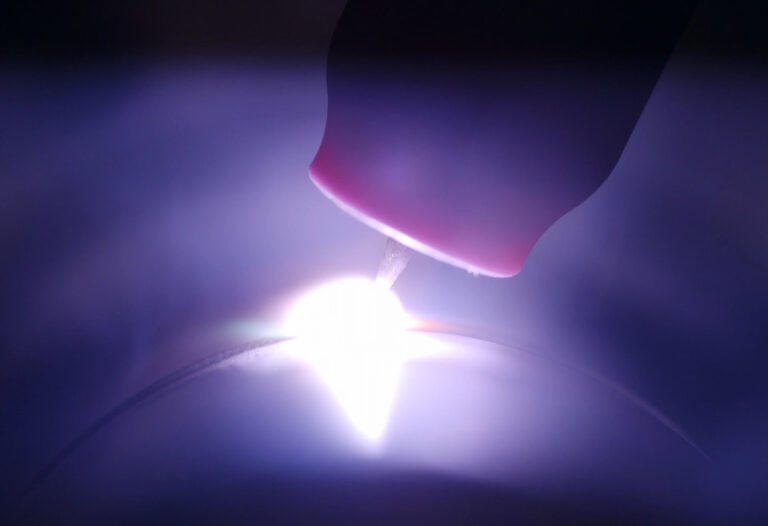

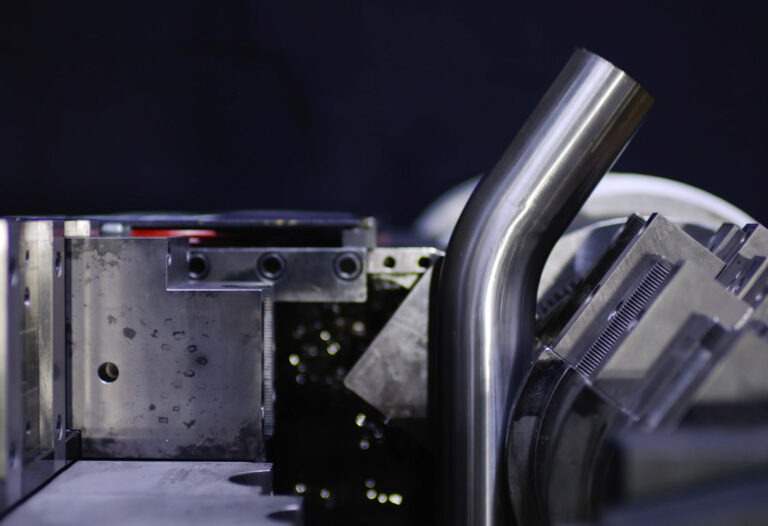

SC-Project is the leading company in the development, design and production of exhaust systems for motorcycles, both racing and road.

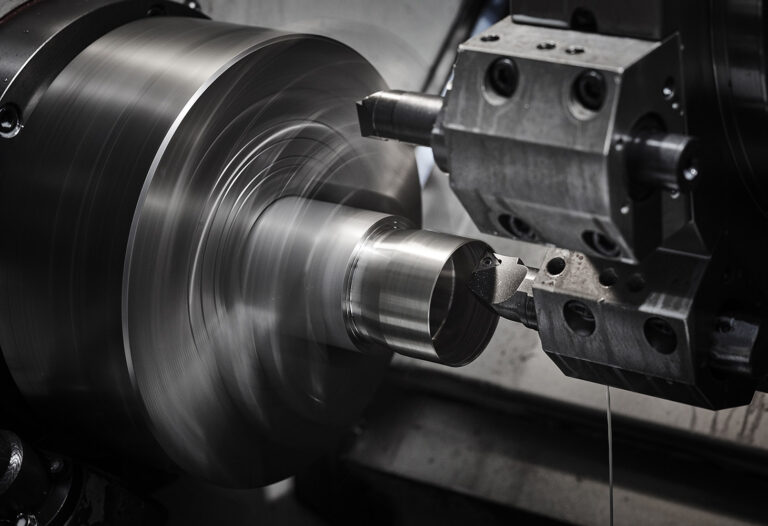

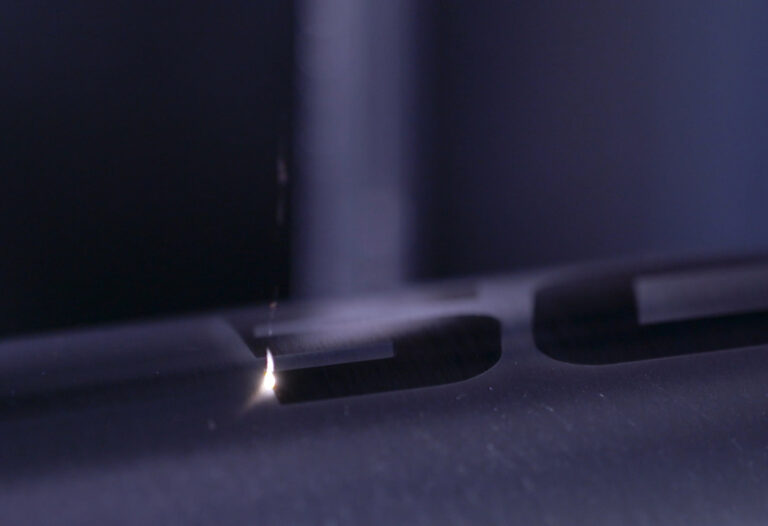

SC-Project was officially established in 2006. Right from the start, the goal is to bring the excellence of “Made in Italy” all over the world. The use of the best materials and the best technologies, combined with design and continuous research, have always distinguished our product.

SC-Project’s headquarters are located in Cassinetta di Lugagnano, in the Milan metropolitan area, a very close distance from the city and not far from Malpensa airport. It is composed of four adjacent buildings (three connected together) that develop a total area of over 15,000 square meters of which 8,000 square meters are covered.

More than 100 employees work in this facility including engineers, technicians, administrators and skilled workers.

SC-Project products are distributed all over the world.